As renewable, low-carbon resources, bioenergies have a vital contribution to make in reducing emissions, particularly in transportation. Bioenergies are therefore a perfect fit with our ambition to become the responsible energy major. As a pioneer in biofuels for more than 20 years as well as a bioplastics producer, we have a role in the future of the bioenergies sector and the development of all biomass conversion pathways.

Bioenergies: Helping to Reconcile Growth and Climate Change

Biomass encompasses all organic material derived from plants, animals and microbes.

Biomass can be converted to produce biofuels and bioplastics, and thereby help meet three major challenges.

Meeting the energy needs of a growing world population

The increase in global energy needs goes hand in hand with global population growth and economic and social development. In the transportation sector, energy needs are increasing by 31% per year. Demand for plastics is growing by 3% annually.

Limiting global warming

According to the 2°C scenario put forward by the International Energy Agency (IEA), the world economy must undertake major changes in order to limit energy-related carbon emissions. One of the drivers identified to achieve this shift is an increase in the share of renewable energies, particularly through the development of biofuels.

More than 20% of worldwide CO2 emissions are attributable to transportation. Biofuels, which lower carbon dioxide emissions by at least 50% compared to fossil fuels, are key to reducing this sector’s environmental footprint. Today, biomass represents the only renewable alternative to fossil fuels in the production of liquid fuels, on which transportation still largely depends. A significant amount of legislation has been passed to encourage and channel the development of biofuels. In Europe, for example, 14% of transportation fuel must come from renewable sources by 2030.

Also offering interesting prospects for reducing the environmental footprint is the development of bioplastics. Polylactic acid (PLA) polymers, for example, are biodegradable and less carbon-intensive than conventional polymers.

Adapting to the changing expectations of customers and society

Conscious of the urgency of combating climate change and sensitive to the issue of sustainable development, our customers are adapting their behavior and expect solutions with a lower environmental impact, including biofuels and bioplastics.

Preparing the Future of Biofuels and Bioplastics

To achieve our ambition of becoming a leader in biofuels and developing innovative bioplastics, we are actively working on all biomass conversion solutions.

We are involved in the two main biomass conversion pathways:

- Thermochemical conversion, which enables biomass to be transformed into a wide range of molecules through the combined action of pressure, temperature and often a catalyst.

- Biotechnology, which uses microorganisms, such as yeast, bacteria or microalgae that are capable of converting both plant matter and inorganic carbon (CO/CO2) into target molecules.

These two pathways are flexible and can be used separately or together to produce a wide array of products from a variety of resources. However, many challenges still lie ahead.

The bioproducts currently available on the market are mainly produced from vegetable oils and sugars. The conversion of resources such as lignocellulose (plant waste) or microalgae (microorganisms that can directly transform CO2 and light into molecules of interest for our markets) is still in the R&D stage.

TotalEnergies is present across the entire value chain, from R&D to industrial production.

Developing our position as a producer and retailer of bioenergies through major industrial projects

As a pioneer in biofuels, for more than 20 years TotalEnergies has been producing ethyl tert-butyl ether (ETBE), a gasoline additive, as well as hydrotreated vegetable oil (HVO), which is used for diesel. We are also Europe’s leading retailer of biofuels, with more than 2.4 million metric tons incorporated into our gasoline and diesel in 2018, and we have developed in-depth knowledge of the markets and customers.

To achieve our ambition of becoming a leader in sustainable biofuel markets, we transformed our La Mède refinery in France into a world-class biorefinery. One of the largest facilities of its kind in Europe, the biorefinery has a capacity of 500,000 tonnes of HVO-type biofuels per year, in order to continue to meet growing demand.

- Learn more about La Mède: France’s first world-class biorefinery

- Find out more about Grandpuits: a zero oil platform manufacturing biofuels and bioplastics

On the bioplastics market, we are developing innovative products that meet the challenges of sustainable development and enable our customers to embrace more conscientious consumption. We are focusing particularly on polylactic acid (PLA), a polymer produced from sugar and starch crops with an environmental footprint one third that of conventional polymers. PLA is currently used mainly in food packaging and textiles as well as in the medical, electronic and automotive industries, and is one of the first renewable polymers able to compete with existing polymers in terms of performance.

In December 2018, together with our partner Corbion, we started up a world-class PLA plant with a capacity of 75,000 metric tons per year. Our ambition is to become the world’s number two PLA supplier.

Harnessing cutting-edge R&D to develop tomorrow’s bioenergies

Biofuel and bioplastic development still poses challenges relating to availability, collection and technology.

As part of our ambition to become the responsible energy major, one of our goals consists in developing technologies to broaden the range of usable resources and designing innovative, heavy-duty and competitive products.

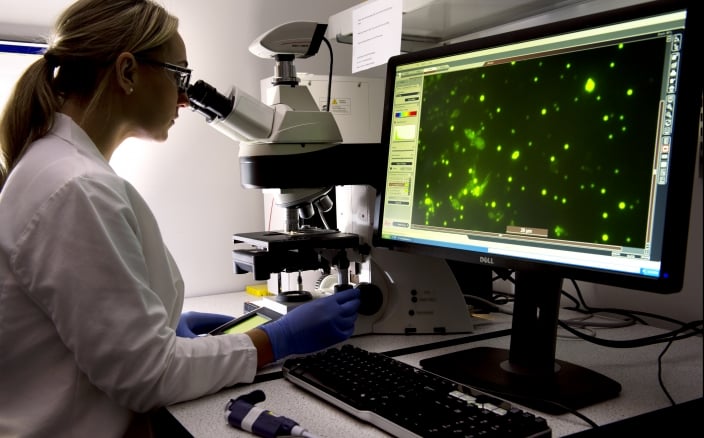

For more than ten years, our R&D teams have harnessed their expertise to bring to light tomorrow’s bioenergies. The utilization of lignocellulose (plant waste) and microalgae (microorganisms that can transform CO2 directly into molecules of interest for our markets) are two focuses of our efforts.

We conduct our research as part of joint projects and top-tier partnerships with start-ups and academic and industrial players, including Renmatix, not to mention the Futurol and BioTfueL consortiums. Developed with five partners, the BioTfueL project aims to transform lignocellulosic biomass such as straw, forest wastes and dedicated crops into biofuels using a thermochemical pathway.

Microalgae also offers promising prospects. To demonstrate the industrial potential of this resource, TotalEnergies is conducting a variety of R&D projects in partnership with players in the research world, such as France’s CEA and China’s Qingdao Institute of Bioenergy and Bioprocess Technology, as well as the Netherlands’ Wageningen University (European Magnificent project).

Learn more about PCV, AlgaePARC, QIBEBT: Proving and harnessing microalgae’s potential